from production to market launch

Rendyr aims to democratize creativity by providing accessible fabrication technology, starting with the Optic - the Portable Laser Cutter, empowering individuals worldwide to unleash their innovative potential without limitations.

Optic - the Portable Laser Cutter

The first portable laser cutter with built-in filtration and infinite workspace capabilities. Optic gives you the ability to create anywhere, such as your studio apartment, garage woodshop, or even onsite for a special project. Simply unfold Optic within seconds to bring the power of laser cutting and engraving to your creative pursuits.

Portability

Easily switch between the compact 4.5 x 6.5 x 24.75 inch storage size and the generous 12 x 18 inch base work area

Built-In Filtration

Laser-generated smoke and fumes are pulled in through the filter where the HEPA and high-activity carbon media capture contaminants

Infinite Workplace

Detach the cutting mat to use Optic directly on surfaces of any size and thickness and cut or engrave your design in sections instructing the software to precisely align each part

Personal Role

-

Developed and optimized manufacturing processes for in-house production of 300+ desktop laser cutters

-

Led the creation and editing of comprehensive assembly documentation

-

Gathered quantitative and qualitative user feedback and suggested design changes to engineering team

-

Established and managed packaging department

-

Collaborated to develop a engaging and intuitive website using UX/UI principles, ensuring seamless user experience

-

Spearheaded the development and execution of content strategies for laser cutting projects, resulting in a significant increase in user engagement

_edited.jpg)

Early Production Builds

As the Optic prototypes started to be consistently made, it became time to build more, define processes, and test for consistency as well as accuracy. My early contributions included learning assembly processes and optimizing them. In addition, space and system planning became imperative to manufacturing systems.

With a long, extensive manufacturing process, the Optic building experience became imperative to investigate and improve upon. I helped encourage design and process changes where pain points impacted the ease of assembly, resulting in both tens of hours cut from the assembly time as well as less frustrating processes.

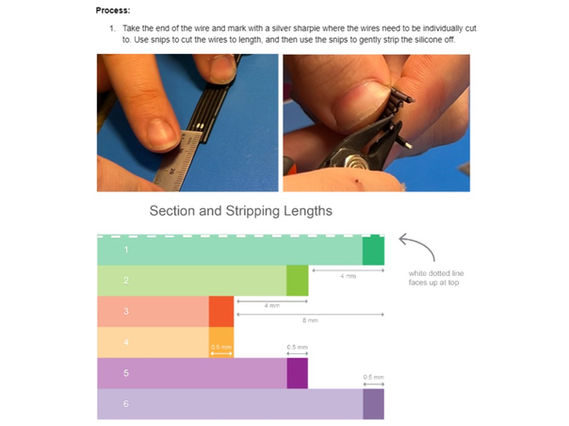

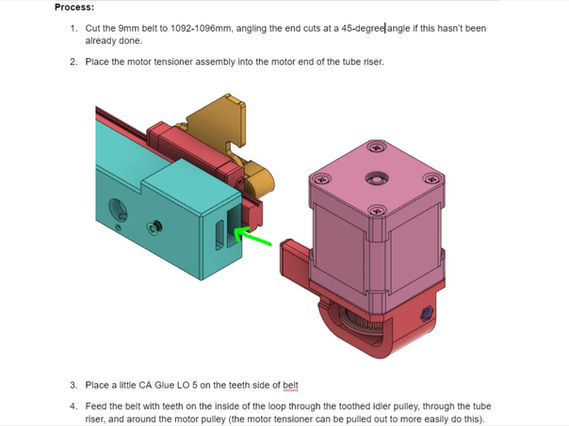

Comprehensive Assembly Documentation

As the business scaled, documentation became required to support the manufacturing process to preserve consistency and record process changes along with tool and material requirements. At this time, I led the creation and editing of hundreds of pages of documentation from laser diode focusing to soldering cables and boards to part installation.

Through the design for manufacturing process and optimizing processes, we were able to take the assembly time of an Optic from over 30 hours to under 15 hours.

Special Thanks

Martin Angst

Grayson Morrow

Robert Worley

Kaelum Hasler

Hans Stahl

Chris Hanks

Paris Parsons

James Trixler

Ron Flanary

Ed Coe

Travis King

Joe Lawson

Mikila Young

Austin Alley

Jarid Scott

Sarah Trixler

Travis Wiehe

Mike Abbott

Vincent

.png)