Designing with care, curiosity, and intention

furniture

waste in the US in

2017 totaled 12.2

million tons with

80.2% ending up in

landfills

a mere 0.3% of

furniture waste sent to

landfills was recovered

for recycling

furniture sales are

estimated to rise 5.3% in

the upcoming year,

bringing them to over

$71 billion

Achieving a Circular Economy

Fast Furniture

Compared to other waste streams, furniture waste is often overlooked because it’s generated less frequently than other consumer and business waste. Unfortunately, furniture waste is a significant issue due to how it often has to be disposed of. It is not easily thrown out or recycled compared to other waste streams.

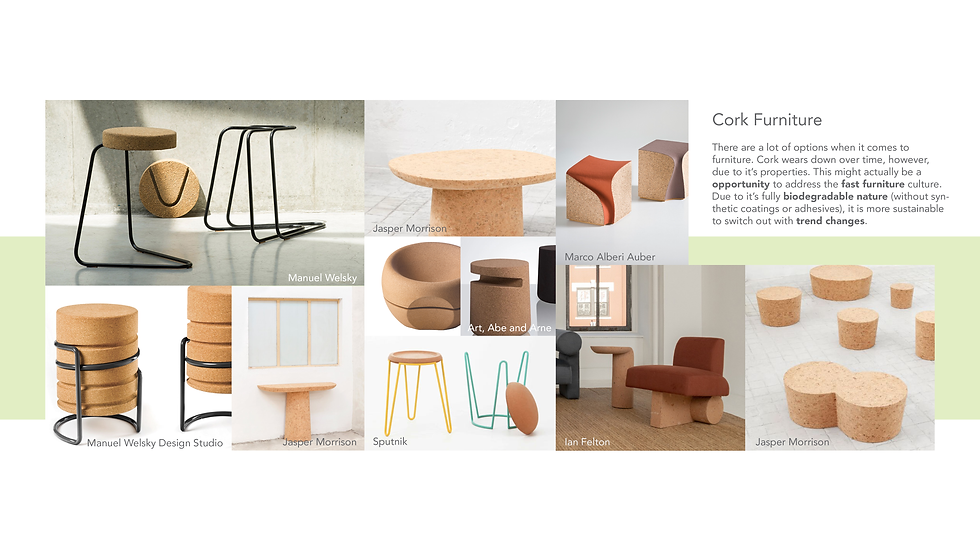

Companies often prioritize low prices to stimulate demand, frequently resulting in the use of lower-quality materials. Consequently, consumers tend to perceive such furniture as disposable rather than suitable for resale or donation. Marisa Donnelly, in her article "What Is Fast Furniture and Why We Should Be Talking About It?", defines fast furniture as a cultural phenomenon driven by convenience and mobility. With many people frequently moving, downsizing, upgrading, or adapting their home design preferences based on current trends, fast furniture strives to offer affordable, trendy, and easily disassembled furniture. A notable example is Ikea, which produces its iconic Billy bookcase every three seconds.

Cork Harvesting

Cork is unique in that trees are not chopped down to harvest the cork. Cork is made from bark that grows back every nine years. A cork oak can be harvested at least 15 times during its lifespan.

Design Goals

Sustainable Materials

Cork is commonly used as wine stoppers, and there is leftover waste from the small cylinders cut from the virgin material. To prevent the scraps from being thrown out, a composite material can be made. While the cork composite does use a binder, which is not fully biodegradable, creating the composite for furniture allows large chunks of material to be produced while integrating a new material stream from an existing manufacturing process.

Versatile Design

To give a cork product value in a consumer’s life, the design should be both functional in a space and versatile in aesthetic. The consumer should want to continue using it over time. The lifetime of a product can reduce waste and add value to the product itself. The more ways or spaces a consumer might be able to use a design, the more likely they are to connect and appreciate its value.

Integrable into Society

It is hard to change current trends and patterns in society. To encourage sustainable solutions to phenomena such as fast furniture, designers have to be aware of consumer tendencies and how to successfully integrate these solutions into current society. Topics to be considered in this design include how to

encourage sustainable interests when investing in furniture.

Cork Molding

This process often utaliizes the waste from making cork wine stoppers. Unlike processes such as CNC routing, there is little scrap to achieve the form desired because just enough scrap material and a biner are used to fill custom molds. For a product with an organic form, including my design intent, this process seemed ideal to get a fluid, rounded form.

Eugene Stoltzfus Architects

Eugene Stolzfus Architects, founded by Eugene Stolzfus, prioritizes environmentally sustainable design in their projects. Inspired by the use of cork floors in kitchen settings, the firm delved into exploring other applications for cork, resulting in the creation of the Libson furniture collection. Unlike cork flooring, this furniture is intentionally designed without a polyurethane finish, allowing wear marks to be sanded off over time. The collection, displayed by Saks Fifth Avenue in New York City, exhibits a clean and modern aesthetic, combining natural cork composite with steel framing across tables, pedestals, and seating.

Material Findings

radii help keep the material from tearing off at edges where there is human interaction

instead of traditional joinery or adhesives, CNC routing allows the cork to sit securely within a steel frame

because liquids don’t penetrate far into the material, paint easily scratches off

water stains don’t easily occur on cork (shown is the bottom of an side table that sat outside for a year)

if done well and sanded after, seams in the cork where two pieces are glued together are not easily visible